Stainless Steel

SUS 303

Specifications

- JIS SUS 303

Summary

- Nuts and Bolts

- Bushings

- Shafts

- Aircraft Fittings

- Electrical Switchgear Compounds

- Gears

Introduction:

Stainless steel 303 is a popular free-machining austenitic stainless steel alloy known for its excellent machinability and moderate corrosion resistance. Composed primarily of iron (Fe) with chromium (Cr) and nickel (Ni) as the primary alloying elements, stainless steel 303 offers a unique set of characteristics that make it highly valuable in various industrial applications. Here's a detailed write-up on stainless steel 303:

Composition:

Stainless steel 303 belongs to the austenitic family of stainless steels and typically consists of the following composition:

- Chromium (Cr): 17-19%

- Nickel (Ni): 8-10%

- Iron (Fe): Balance

- Carbon (C): ≤0.15%

- Manganese (Mn): ≤2%

- Silicon (Si): ≤1%

- Phosphorus (P): ≤0.20%

- Sulfur (S): 0.15-0.35%

The addition of sulfur to stainless steel 303 enhances its machinability, making it easier to cut, drill, and machine compared to other stainless steel grades.

Properties:

- Excellent Machinability: Stainless steel 303 is renowned for its exceptional machinability, making it the preferred choice for applications requiring extensive machining operations. The addition of sulfur promotes the formation of manganese sulfide inclusions, which act as chip breakers during machining, resulting in improved chip control and surface finish.

- Moderate Corrosion Resistance: Stainless steel 303 offers moderate corrosion resistance in mildly corrosive environments, such as atmospheric conditions and freshwaters. While it is less corrosion-resistant than some other stainless steel grades, it is still suitable for many applications where corrosion resistance is not the primary consideration.

- Good Mechanical Properties: Stainless steel 303 exhibits good mechanical properties, including high tensile strength, yield strength, and hardness. It provides reliable performance in various structural and load-bearing applications where strength and durability are essential.

- Weldability: Stainless steel 303 is generally weldable using standard welding techniques, such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW). However, precautions should be taken to avoid sensitization and subsequent corrosion in the heat-affected zones.

- Surface Finish: Stainless steel 303 can achieve a smooth and shiny surface finish, making it suitable for decorative and aesthetic applications where appearance is important. It is commonly used in architectural, automotive, and consumer goods applications.

- Non-Magnetic: Stainless steel 303 is non-magnetic in the annealed condition but may become slightly magnetic after cold working or machining operations. This property is advantageous in applications where magnetic compatibility is required.

Applications:

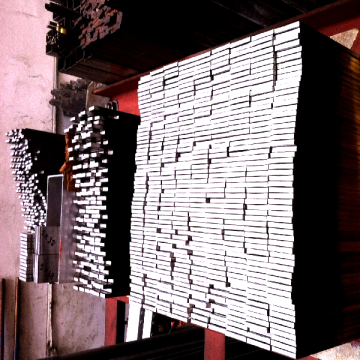

- Machined Components: Stainless steel 303 is extensively used for manufacturing machined components such as screws, bolts, nuts, shafts, fittings, and bushings. Its excellent machinability allows for the production of intricate and precision parts with tight tolerances.

- Automotive and Aerospace: Stainless steel 303 finds applications in the automotive and aerospace industries for manufacturing fasteners, fittings, and components requiring both strength and machinability. It is used in engine components, fuel systems, and airframe structures.

- Electronic and Instrumentation: Stainless steel 303 is utilized in electronic and instrumentation applications for manufacturing connectors, housings, and precision components. Its machinability and corrosion resistance make it suitable for producing complex parts with high dimensional accuracy.

- Consumer Goods: Stainless steel 303 is used in the production of consumer goods such as kitchen utensils, appliances, and hardware due to its ease of machining and aesthetic appeal. It is commonly found in handles, knobs, faucets, and decorative trim.

- Medical Devices: Stainless steel 303 is employed in the medical industry for manufacturing surgical instruments, dental equipment, and medical devices requiring biocompatibility and machinability. It is used in components such as screws, pins, and bone plates.

Conclusion:

Stainless steel 303 is a versatile alloy with excellent machinability and moderate corrosion resistance, making it suitable for a wide range of applications across various industries. Its unique combination of properties, including machinability, corrosion resistance, strength, and aesthetic appeal, makes it indispensable for manufacturing critical components and structures requiring precision, reliability, and performance. Whether in automotive, aerospace, electronics, consumer goods, or medical applications, stainless steel 303 continues to demonstrate its value as a versatile and effective engineering material.

Share