Bronze

Manganese Bronze

Specifications

- C86300 SAE 430B

Summary

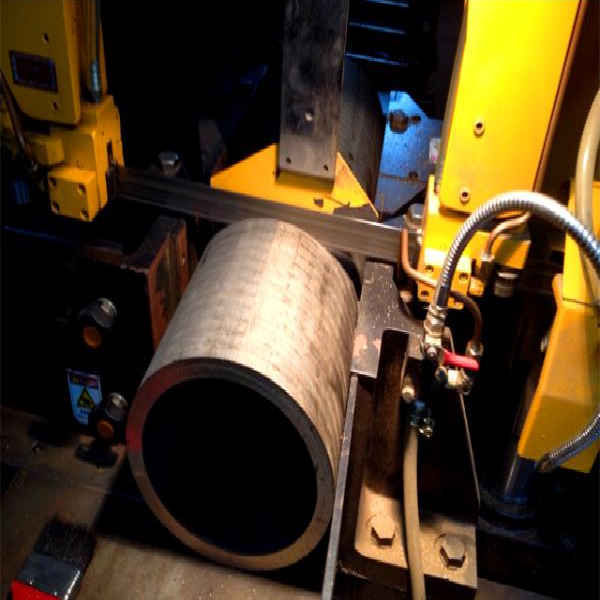

- Extra heavy duty high strength allow for large valve stems, gears, cams, slow speed heavy load bearings, screw down nuts and hydraulic cylinder parts

Introduction:

Manganese bronze C86300, also known as SAE 430B bronze, is a specialized alloy recognized for its excellent combination of mechanical properties, corrosion resistance, and wear resistance. Comprised primarily of copper (Cu) with manganese (Mn) as the primary alloying element, C86300 offers a unique set of characteristics that make it highly valuable in various industrial applications. Here's a detailed write-up on manganese bronze C86300:

Composition:

Manganese bronze C86300 primarily consists of copper as the base metal, with manganese added as the primary alloying element. The typical composition of C86300 alloy includes approximately:

- Copper (Cu): 58-62%

- Manganese (Mn): 2.5-3.5%

- Other trace elements: Iron (Fe), Zinc (Zn), Lead (Pb), and Tin (Sn) in small amounts.

The precise composition may vary slightly depending on specific manufacturing requirements and standards.

Properties:

- High Strength and Hardness: Manganese bronze C86300 exhibits excellent strength and hardness, making it suitable for applications requiring structural integrity and load-bearing capabilities. It can withstand high mechanical stresses and loads without undergoing deformation or failure, providing reliability and longevity in demanding environments.

- Corrosion Resistance: C86300 bronze offers good corrosion resistance, particularly in freshwater and non-corrosive environments. However, it may not be as resistant to corrosion as some other bronze alloys in marine or highly corrosive environments.

- Wear Resistance: One of the key advantages of C86300 bronze is its exceptional wear resistance, making it suitable for applications subjected to heavy loads, friction, and abrasive wear. It maintains its dimensional stability and surface integrity even under harsh operating conditions, contributing to extended service life and reduced maintenance requirements.

- Machinability: C86300 bronze is relatively easy to machine and fabricate using standard machining techniques. Its machinability allows for the production of intricate components with precise dimensions, contributing to manufacturing efficiency and cost-effectiveness.

- High Load Bearing Capacity: Due to its high strength and wear resistance, C86300 bronze is commonly used in applications requiring high load-bearing capacity, such as bushings, bearings, and gears. It provides reliable performance and extended service life in heavy-duty and high-stress environments.

- Good Thermal Conductivity: C86300 bronze possesses good thermal conductivity, allowing for efficient heat transfer and dissipation. This property is advantageous in heat exchangers, condensers, and other thermal management applications where effective heat exchange is essential for optimal performance.

Applications:

- Bearings and Bushings: C86300 bronze is widely used in the manufacture of bearings, bushings, and thrust washers for various industrial applications, including automotive, machinery, and heavy equipment. Its excellent wear resistance and high load-bearing capacity make it ideal for high-stress and heavy-duty applications.

- Gears and Gear Components: C86300 bronze is utilized in the production of gears, gear bushings, and other gear components requiring strength, wear resistance, and dimensional stability. It ensures smooth operation and reliable performance in gear assemblies for machinery and equipment.

- Marine Hardware: While not as corrosion-resistant as some other bronze alloys, C86300 bronze is used in marine hardware such as propeller shaft bearings, stern tubes, and rudder bearings due to its high strength and wear resistance. It provides reliable performance in marine applications subjected to heavy loads and abrasive wear.

- Valve and Pump Components: C86300 bronze finds applications in valve and pump components such as valve seats, pump impellers, and pump housings due to its wear resistance and high load-bearing capacity. It ensures reliable fluid handling and extended service life in fluid processing systems.

- Industrial Machinery: C86300 bronze is employed in various industrial machinery and equipment for components requiring high strength, wear resistance, and corrosion resistance. It is commonly used in bushings, bearings, and wear plates for heavy-duty applications.

Conclusion:

Manganese bronze C86300 is a versatile alloy with a wide range of applications across diverse industries. Its exceptional combination of mechanical properties, corrosion resistance, and wear resistance makes it indispensable for manufacturing critical components and structures requiring durability, reliability, and performance. Whether in bearings, gears, marine hardware, valve components, or industrial machinery, C86300 bronze continues to demonstrate its value as a versatile and effective engineering material.

Share